Company Formation in Colombia: Incorporation Guide for Foreign Businesses

To incorporate a company in Colombia, you must follow several clear steps, beginning with selecting the business structure that aligns with your needs. Registering a company to explore opportunities in Colombia is a straightforward process when supported by the right expertise, ensuring compliance with the country’s well-defined rules and procedures.

A key part of this will be managing compliance, which will involve registering with the local revenue service DIAN in order to recieve a unique tax identification number known as a NIT. You will also have to register with the local chamber of commerce, for example in Bogota. The whole process will take up to six weeks if you partner with a local specialist.

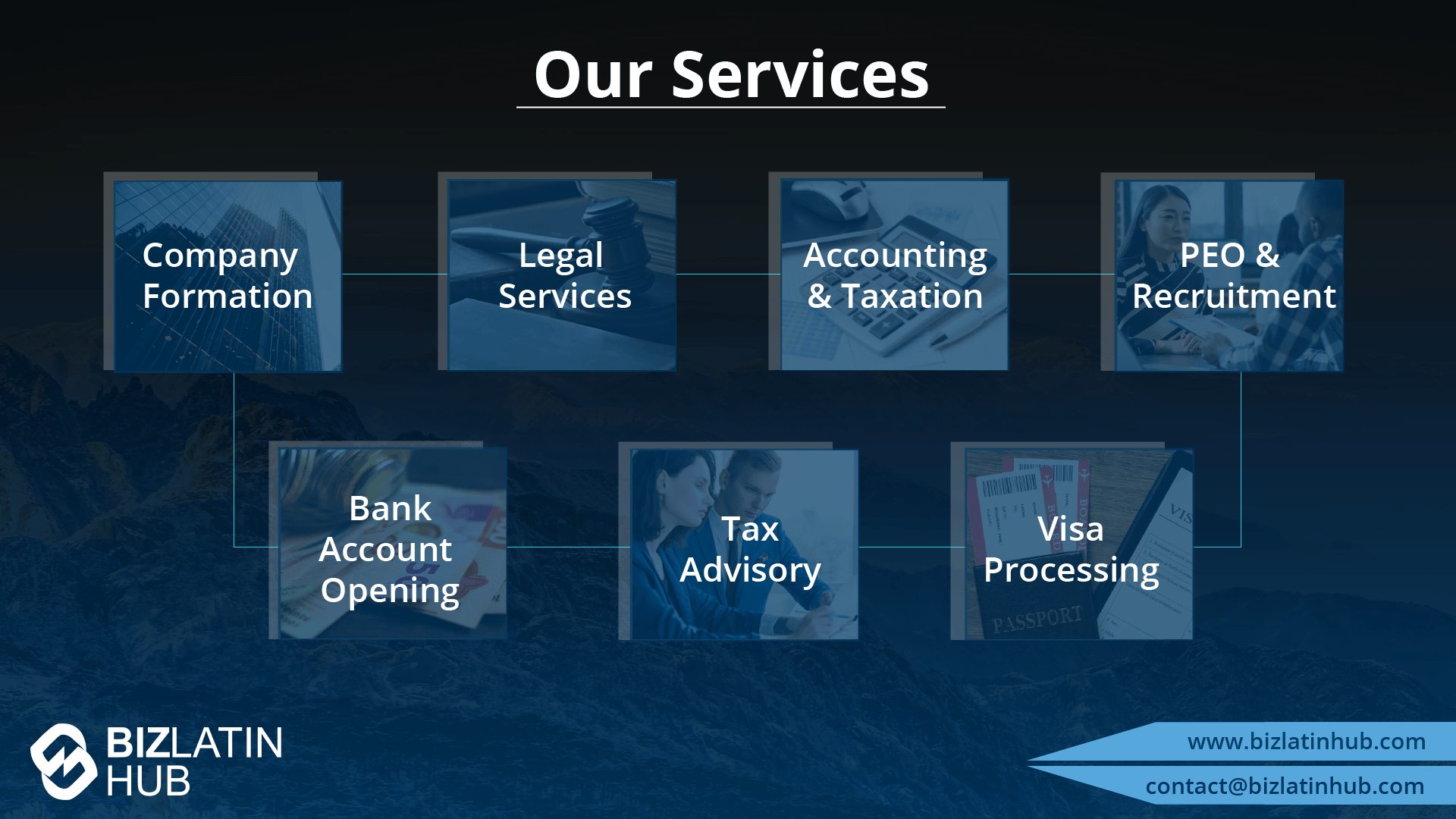

Biz Latin Hub offers unparalleled local knowledge and a comprehensive suite of back-office services, allowing you to focus on growing your business and do business in Colombia. With a dedicated in-country office, we not only know how to deal with the paperwork but also how to do business in this often complex country.

Key Takeaways On How To Incorporate a Company in Colombia

| Is Foreign Ownership Permitted in Colombia? | Yes, its possible to have 100% foreign ownership in Colombia. |

| Key steps to register a company in Colombia: | Step 1: Establish the foundations of the company. Step 2: Understand the available legal structures. Step 3: Register your company at public institutions to incorporate a company in Colombia. Step 4: Open a corporate bank account. Step 5: Create an entity incorporation document. Step 6: Hire a legal representative to incorporate a company in Colombia. Step 7: Comply with the laws regarding hiring employees. |

| What Are The Common Legal Entity Types In Colombia? | The three most common are: Sociedad Anónima (S.A.) Sociedad Limitada (Ltda.) Sociedad por Acciones Simplificada (SAS) |

| What Details Are Necessary To Incorporate a Company in Colombia? | A name for your legal entity. Shareholder identification documentation. Confirm the business activities and corporate purpose. Minimum initial capital to be registered. |

| Why Choose to Setup a Company in Colombia? | A skilled workforce, competitive labor costs, regulatory reforms, tax incentives, and growing growing infrastructure. |

How to Incorporate a Company in Colombia – Step-by-Step Guide

These are the 7 steps that describe the process of incorporating a company in Colombia:

- Step 1: Establish the foundations of the company.

- Step 2: Understand the available legal structures.

- Step 3: Register your company at public institutions to incorporate a company in Colombia.

- Step 4: Open a corporate bank account.

- Step 5: Create an entity incorporation document.

- Step 6: Hire a legal representative to incorporate a company in Colombia.

- Step 7: Comply with the laws regarding hiring employees.

1. Establish the foundations of the company

To establish a company in Colombia, it’s essential to verify the availability of your chosen company name. Your legal business name and trademark can be different.

Be sure to write and present your business’ bylaws. This agreement should include all relevant information on your company, such as how it will function and the activities it will be involved with.

If you are establishing a company in Bogotá, the full process of getting a Tax ID (Registro Único Tributario or RUT) can be completed in the Chamber of Commerce. However, if you are going to be located in another city, additional steps will be needed. First, you must apply for a provisional RUT, and only after receiving it can you apply for the final RUT before DIAN. This is a crucial step.

2. New company formation: Understand the available legal structures

There are three legal structures a company can fall into in Colombia. You can choose the one that best suits your needs. They include:

- Limited company.

- Joint-stock company.

- Simplified stock company.

A simplified stock company (SAS) is the simplest option for most foreign investors incorporating a company in Colombia because it requires fewer formalities. The law permitting the establishment of a SAS was passed in 2008, and it remains an ideal option for both local and foreign investors.

3. Register your company at public institutions to incorporate a company in Colombia

There are three primary institutions you will deal with when incorporating a company in Colombia. They include:

- The Chamber of Commerce.

- Colombian Tax Authority (DIAN).

- Local bank of your choice.

The Chamber of Commerce is responsible for regulating the creation of new companies in Colombia. It ensures that your registration adheres to the current legal structures and policies. It will also provide a certificate that demonstrates the existence and legal status of your company.

This certificate will be requested by most private and public entities existing in Colombia once you begin operating your business.

The Tax Authority registers your business into the tax system. This registration earns you a unique tax number (NIT), which will serve as a general identification and enable you to present the mandatory tax declarations.

Additionally, you’ll be required to establish a company bank account, which will serve operational purposes and receive foreign investments.

4. Open a corporate bank account

Opening a corporate bank account is a straightforward process. You will need to present the Existence Certificate from the Chamber of Commerce, the Tax ID certificate (RUT), the ID of the legal representative, and the opening balance sheet of the company.

Keep in mind that some banks have specific requirements for opening an account.

5. Create an entity incorporation document

You will need an incorporation document highlighting the names and personal information of all partners involved in the business. It should also indicate the name of the company and the activities it will be performing in Colombia. It is also necessary to outline:

- Capital structure.

- The board of directors.

- Partner responsibilities.

- Causes of termination.

6. Hire a legal representative to incorporate a company in Colombia

Your company must have a legal representative who can be different from the company owners. This person is responsible for company operations, authorizing tax declarations, and signing all contracts and legal documents.

7. Comply with the laws regarding hiring employees

The final step in the process of incorporating a company in Colombia affects the hiring of employees. You must register your business with the Family Compensation Fund, the Colombian Family Institute, and the Governmental Learning Service, and fill out a unique form for all these agencies.

You will also need to register your employees for public health coverage. Employees have the right to choose their desired provider, to which your company has to submit the required form.

Your company must also affiliate itself with a pension system. You can register with the public fund or other private funds. However, you can’t choose the pension fund for your employees as they have the right to choose their preferred fund.

Registering your business with the Labor Risks Administrator is also essential. This agency helps in covering professional illness and workplace injury cases. You have to pay monthly contributions to the program and protection starts 24 hours after submitting the form.

Types of Companies You Can Register in Colombia

Colombian law recognizes various forms of business entities, but the most common ones are:

- Sociedad Anónima (S.A.): This type of company is similar to a public limited company (PLC). It requires at least five shareholders and a minimum capital contribution of 100 times the monthly legal minimum wage.

- Sociedad Limitada (Ltda.): This is similar to a limited liability company (LLC) in other countries. It requires at least two partners and a minimum capital contribution of 100 times the monthly legal minimum wage.

- Sociedad por Acciones Simplificada (SAS): This is a simplified stock corporation designed to provide a more straightforward and faster incorporation process compared to the traditional S.A. and Ltda. companies. It requires at least one partner and has no minimum capital requirements.

- Empresa Unipersonal: This is a sole proprietorship, where the business is owned by a single individual. There is no minimum capital requirement, and the owner is responsible for all obligations of the business.

The S.A.S is our recommendation for the vast majority of companies due to its streamlined and efficent incorporation process with no minimum investment necessary from the outset. A large advantage of a simplified stock company is the ability to make the articles of incorporation a private document.

The S.A.S is the most common type of legal entity in Colombia and is popular within the business community for businesses large and small. Compared to other types of legal structures in Colombia, it has been praised by investors for its flexibility, specifically regarding the incorporation process and the large freedom afforded to shareholders to establish their own terms and conditions.

Differences between an LTDA and a S.A.S. in Colombia

| S.A.S | LTDA | |

| Incorporation | Established through an authenticated private document | Established through a public deed before a notary |

|---|---|---|

| Number of Shareholders | A minimum of one | A minimum of two shareholders and a maximum of 25 shareholders |

| Liability | Shareholders are liable only up to the amount of their respective capital contributions | Shareholders are liable only up to the amount of their respective capital contributions |

| Capital | Capital is divided into shares of equal value, and the payment is not stipulated | Capital is divided into equal-value portions and must be fully paid at the time of the company’s incorporation |

Capital and banking requirements in Colombia

You will have to open a local bank account in order to do business in Colombia. First, you will need to choose a bank that operates in the country. This includes both Colombian entities and international ones that cover a number of countries. They include:

- Banco de Bogotá

- Bancolombia

- Davivienda

- Banco Popular

- HSBC

- Citibank

- JPMorgan Chase

- BBVA

You will need to gather a number of documents to provide to the bank. While the precise details vary according to institution, it will generally include: a copy of the RUT (pre-taxpayer registration), Power of Attorney of the Legal Representative (if applicable); Copy of the ID of the Legal Representative(s) of the company (if applicable); Certified financial statements; Personal identification documents.

Once you have chosen a provider to bank with, you are ready to begin the process of opening a corporate account. In Colombia, this process involves getting a pre-taxpayer number, waiting for the bank to check your company information and making a minimum deposit.

Once you have completed each of the steps and your corporate bank account is established, the DIAN will issue the permanent tax ID for your corporation. Then you will be fully able to operate in the Colombian fiscal system.

Colombia Company Registration Requirements for Foreign Investors

The minimum requirements to incorporate a SAS – Sociedad de Acciones Simplificada in Colombia are:

- Confirm the legal name of the entity.

- A minimum of (1) shareholder, which can be either a natural person (i.e. individual) or legal person (i.e. entity.)

- Appoint a legal representative within the bylaws of the company.

- Confirm the business activities and corporate purpose of the company.

- A minimum capital of USD$400 should be transferred by the shareholder upon opening the bank account.

- Register a fiscal address within the country and use it for official correspondence.

Important Tip(s):

Based on experience, we would always recommend a minimum capital of USD$1,000 and should be commensurate with the type of business activities.

The legal representative will need to be resident in Colombia, although does not have to be a Colombian national. They will act for the company in all legal interactions. This can also be done through a power of attorney (POA) if you wish.

While your fiscal address needs to be within Colombia for official correspondence and so forth, you are free to operate virtually if you so wish.

What do You Need to Get Started With Your Company Formation in Colombia?

To proceed with incorporating an SAS in Colombia, you will need to provide the following:

- A name for your legal entity.

- Shareholder identification documentation.

- Confirm the business activities and corporate purpose.

- Minimum initial capital to be registered.

Important Tip: We always recommend having a preferred legal name and two alternatives in case the primary legal name is unavailable.

Colombian tax compliance guidelines

All companies operating in Colombia must adhere to International Financial Reporting Standards (IFRS), also referred to as Normas Internacionales de Información Financiera (NIFF) in Spanish. When engaging an accountant in Colombia, ensure they are certified in this process. The National Tax Statute and Decree 2649 of 1993, which mandates generally accepted accounting principles (GAAP) as accounting standards, are also relevant here. Double taxation is not permitted under Colombian law.

Businesses in Colombia are required to submit monthly tax reports starting from the creation of their first invoice. These reports encompass cash flow statements, as well as monthly, quarterly, and annual reports, ensuring compliance. Payroll (Nominal) mandates monthly reports for employees receiving benefits to maintain compliance.

Even inactive companies or startups have a minimum filing requirement of quarterly reports, and failing to file results in significant fines imposed by the DIAN, making it a key area to get right. Financial statements must be prepared in Spanish, and bookkeeping must also be in Spanish.

Statutory auditor requirements in Colombia

By law, all S.A companies must have an auditor for their finances. This is also true of branches of foreign companies that are operating in Colombia. For both Ltda and S.A.S company types, an auditor is only legally necessary under certain circumstances. This may be because the business operates in a sensitive or strategic field such as healthcare or finance, or because of its size.

The latter kicks in for companies that hold assets equal to at least 5,000 Colombian monthly minimum wages (SMLV) or have annual revenue equal to at least 3,000 SMLV. In 2025 this works out as COP$7,117,500,000 (approx USD$1.7m) and COP$4,270,500,000 (approx. USD$1m) respectively. Of course, all companies, regardless of size, are able to voluntarily contract an auditor.

FAQs to incorporate a company in Colombia

Answers to some of the most common questions we get asked by our clients.

To incorporate a company in Colombia, the standard process includes selecting a legal structure (typically an SAS), reserving the company name, drafting the bylaws, appointing a legal representative, registering with the Chamber of Commerce, obtaining a Tax ID (NIT) from DIAN, and opening a corporate bank account. The process is typically handled in Spanish and may require apostilled documents from foreign shareholders.

Foreign investors commonly register three types of companies in Colombia: the Simplified Stock Company (SAS), which is the most flexible and preferred model; the Corporation (S.A.), which is more complex and used for publicly traded companies; and the Limited Liability Company (Ltda.), suitable for smaller entities with up to 25 shareholders. SAS is the most recommended option due to its streamlined setup and 100% foreign ownership allowance.

The full process of incorporating a company in Colombia usually takes between 4 to 6 weeks. This includes document preparation, local filings, tax registration, and bank account setup. The timeline may vary depending on whether apostilled documents are required and the availability of the legal representative.

Basic requirements include a company name, legal structure, at least one shareholder (individual or legal entity), a legal representative based in Colombia, a registered fiscal address, and bylaws. Foreign shareholders must provide apostilled copies of passports and corporate documents, and all documents must be translated into Spanish where applicable.

Companies incorporated in Colombia are subject to corporate income tax, currently around 33%. Additional taxes include VAT (19%) for applicable goods and services, and employer social security contributions if hiring staff. All companies must register with DIAN and fulfill monthly and annual tax filing obligations.

Why choose Colombia to incorporate a company?

Biz Latin hub can help you enter this dynamic economy as smoothly as possible, as our depth of knowledge is unparalleled in the country.

The substantial number of young and skilled workers leads to competitive labor costs. Colombia’s growing workforce is a big reason businesses have been looking to expand into the country. Colombia has made significant strides in improving its business climate through regulatory reforms that simplify bureaucratic processes and provide incentives for foreign investment. For example, the government offers tax incentives and has established free trade zones for foreign entrepreneurs to incentivize company incorporation.

Colombia has abundant natural resources, especially agriculture, mining, and renewable energy. The ongoing enhancements in infrastructure and transportation networks also streamline business operations.

Additionally, the country’s diverse and growing consumer base makes Colombia a promising market for companies seeking growth in Latin America.

Biz Latin Hub can help you to incorporate a company in Colombia

Colombia is an attractive destination if you are looking to expand your business operations or start a new business. However, before you get everything up and running, you need to complete the company registration process.

Biz Latin Hub offers tailored business services, including company formation, legal services, accounting/taxation services, and visa processing. Contact us now and see how we can assist you in registering your new company in Colombia.

Learn more about our authors and team.